Design for Additive Manufacturing and Reverse Engineering

Create and validate design suitable for additive manufacturing processes to ensure that parts can be feasibly manufactured using 3D printing. Reverse engineering involves scanning and modelling any existing part and creating the digital design for further process or record keeping.

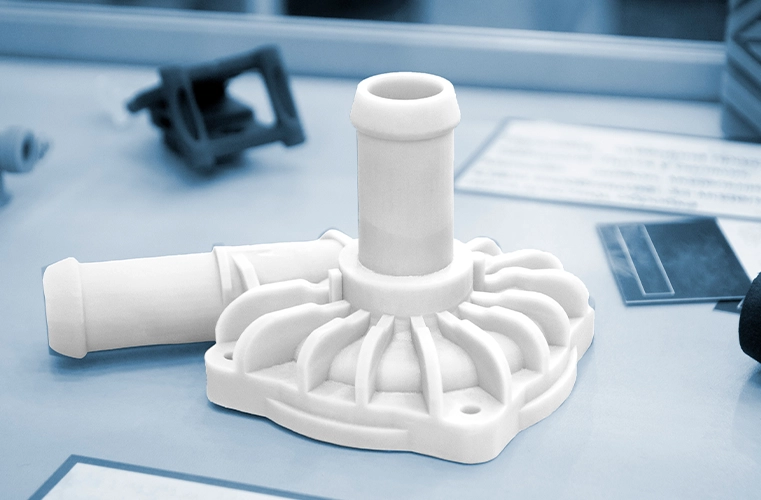

SLA

Stereolithography (SLA) is the most popular resin based 3D printing process. It stands out due to its ability to produce accurate, isotropic, water-tight and smooth prototypes and end use parts.

Read More

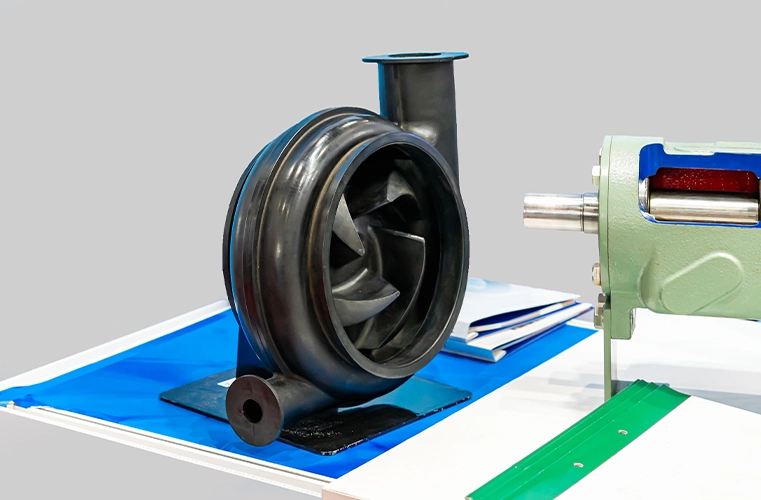

SLS

Selective Laser Sintering (SLS) is a type of powder bed fusion, one of the oldest and most respected 3D printing technologies.

Read More

DLP

Resin based small format 3D Printing technology for quick turnaround times. Various material choices are possible.

Read More

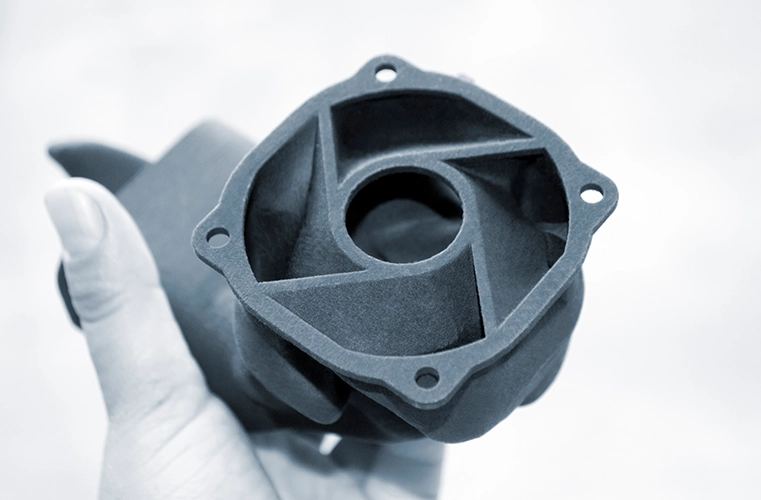

MJF

Powder based 3D Printing technology for strong, durable and functional parts using nylon materials.

Read More

Metal

Powder based 3D Printing technology using various metals to quickly manufacture prototypes or end use parts for various applications.

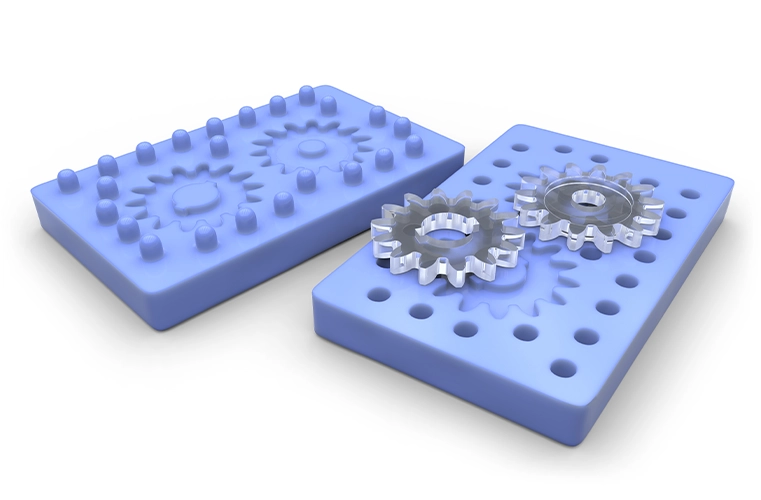

Vacuum Casting

Vacuum Casting / Silicon Molding is a manufacturing process in which a silicone mold is used to cast polymer or rubber parts, generally for prototyping or low-volume production.

Read More

CNC Machining

Post Processing

Various post processing options like painting, joining, surface treatment, screen printing, etc. to ensure your parts have the detail and finish you need.